X-Carve: Easel - Cutters

Introduction

One of the most common questions when using a CNC cutting tool is "What bit should I use?" Cutting tools, often shorthanded to "cutters" or just "bits", are one of the most important parts of successfully completing a project on the X-Carve.

Cutting tools come in a wide variety of sizes, styles, and materials. The important characteristics are diameter, length, cutter material, cutter geometry, flute style, and flute count. Spark is working to develop and maintain a library of basic tools for member use, but members should expect to buy their own cutters for most projects.

Geometry

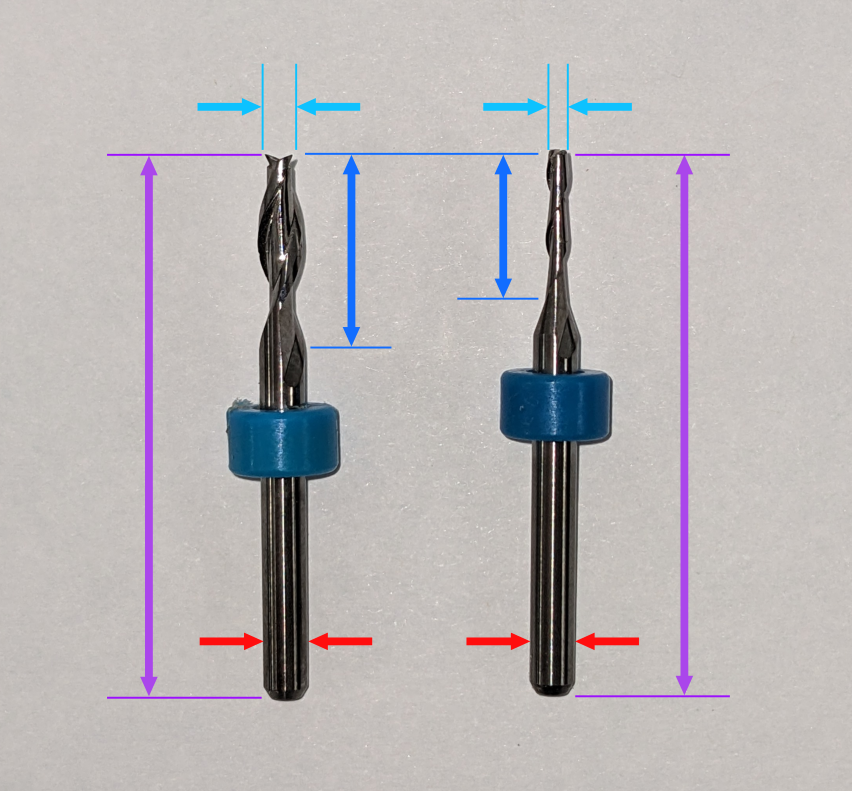

Cutter Diameter

- Shaft (or Shank) Diameter: The diameter of cutter shaft, which is installed in the collet of the spindle router.

- The Spark X-Carve can accept cutting tools with shanks either 1/4-inch (0.25 inches) or 1/8-inch (0.125 inches)

- Cutting Diameter: The diameter of the sharp portion of the cutting tool

- Cutting diameters can range from 1/32-inch up through 1/4-inch

Larger cutters are available, but should not be used on the X-Carve without permission from the Woodshop Leads. Generally, the largest diameter cutting tool which will fit in the project should be used. It is also possible to use large cutters to remove the bulk of material, then smaller cutters to machine the details.

Cutter Length

- Overall Length: The overall length of the cutting tool

- Cutting length: The length of the sharp portion of the cutting tool

- Cutting length limits the maximum depth of cut on a workpiece

A shorter cutter is a stiffer cutter under load, which gives a better surface finish. The shortest available cutter should be used for any given project. At no point should the total cutting depth exceed the length of cut of the cutting tool.

Cutter Material

Cutting tools can be formed out of a number of materials, most commonly high speed steel (HSS) or tungsten carbide (usually just described as “carbide”). Carbide tools will usually outperform HSS tools, but will also cost more. The cutter material will influence spindle speed and feed rate. A variety of specialty surface coatings such as titanium nitride or chromium nitride are also available on some tools. These are often added to extend tool life in high production environments, and will not often be encountered at Spark.

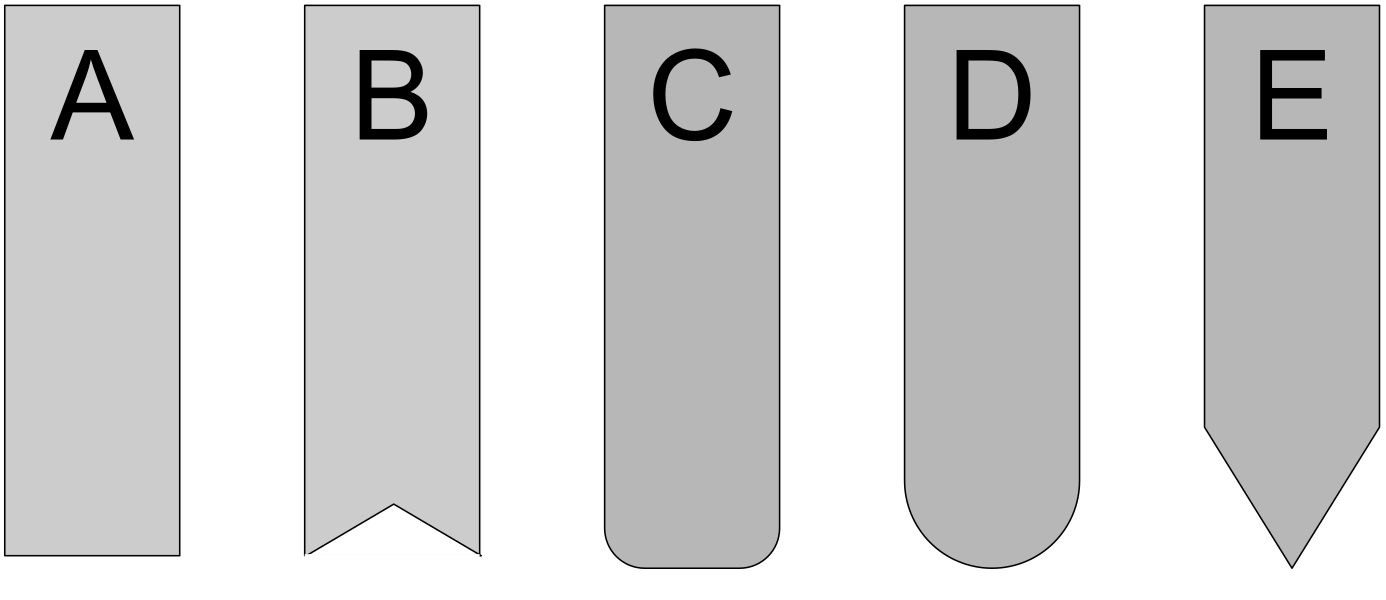

Tip Shape

Cutting tools can be found in a large number of profiles, but the most common are shown in the diagram below. For the Spark X-Carve, cutting tools should be capable of plunge cutting. Plunge cutting is when the cutting tool is driven straight into the workpiece like a drill bit. The Easel software uses straight plunge cuts for material entry in nearly all cases.

- Square profile cutters are the most common, and used for a variety of applications. Square cutters are often used to cut complete profiles out of material or rough out bulk material before moving to a finer or different cutter when doing 3D surface milling. Square profile cutters are very rarely completely square. There is usually a very small radius or chamfer at the bottom corner. Many, but not all, square cutters are capable of plunge cutting.

- Fishtail cutters, commonly used on plastics and wood, are designed to minimize the radius on the bottom corner, to produce clean square cuts in pockets. However, fishtail cutters tend to be delicate and should not be used for heavy work. Most fishtail cutters are not capable of plunge cutting.

- Bullnose, or radiused corner cutters, are used when a rounded bottom corner to a pocket or hole is desired. Bullnose cutters are otherwise similar to square profile cutters.

- Ball end cutters are used where complex 3d curves or surface geometries are required. However, to achieve that effect, a very large number of machining passes are required in close proximity. The standard CAM software at Spark, Easel, does not support 3D surfacing operations, so the use of ball end cutters is currently limited.

- V-groove cutters are available in different diameters and tip angles for different applications. The width of the cut is dependent on the depth of the cut, and deep cuts will require significantly more work by both cutter and machine. Careful attention to depth of cut on repeated passes is required when using V-groove cutters. Easel has some capacity for using these bits for lettering and sign making.

Flute

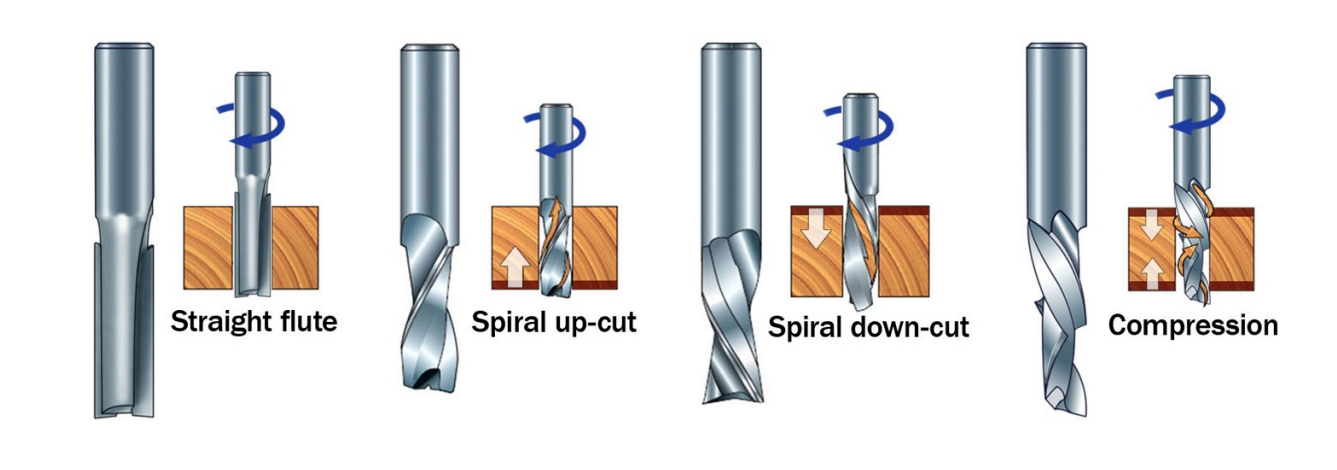

The flute is the groove in the cutting tool. This groove allows cut material, in the form of chips, to be removed from the cutting area. Cutting tools come with a variety of flute geometries and numbers.

Flute Styles

Four styles of flute are commonly available: straight, upcut, downcut, and compression.

- Straight flutes: Straight flute cutters are general purpose bits. Straight flutes give a reasonable cut quality on most materials, and have reasonable chip extraction capability. Straight flute work well on solid wood.

- Spiral up-cut flutes: Up-cut flutes are very good at chip extraction, and give excellent finish to the bottom of pockets and through cuts. However, up-cut flutes may give a fuzzier finish to the top of the material being cut, and will try to lift the workpiece off the machine table. up-cut flutes work well on plastics.

- Roughing flutes: some cutters, generally spiral up cutters, will have scalloped edges to the cutting surface and flute. These edges reduce chatter and act as chip breakers, allowing a higher chip load. This allows them to take more material out faster, at the expense of surface finish. They are more common in larger cutter sizes, though some small cutters optimized for plastics will display similar geometry.

- Spiral down-cut flutes: Down-cut flutes give good quality cuts on the top face of the workpiece, at the expense of splitting or fraying on the bottom of a through cut. Chip extracting is difficult; shallow passes and active dust collection are required when cutting grooves to prevent packing and remachining of chips. The downward force helps when cutting thin pieces. Down-cut flutes work well for fine details such as inlay. These cutters should not be used without first discussing with the Woodshop Leads.

- Compression flutes: Compression flutes have up-cut geometry at the bottom, and down-cut flutes on the top. Compression flutes give good finish at both surfaces, as these cutters are intended to cut through laminates or veneered material in a single pass. Compression flutes should not be used without first discussing with the Woodshop Leads.

Flute Count

Flute counts for wood and plastic generally range from one to four flutes. Cutters with up to a dozen flutes may be used for larger machines or metalworking operations. Due to limitations in the speed control on the router mounted on the X-carve, it will be rare to use cutters with more than three flutes while at Spark.

- Single flute cutters have large flutes, which means the flute can remove large chips during cutting.

- Increasing the number of flutes reduces the individual flute size, limiting the size of the chip.

- High flute counts generally mean a more rigid cutter, allowing better surface finishes for a given length.

- As a general rule, more flutes mean a better surface finish and faster material removal. However, the X-Carve is extremely limited in feed rates, and is not capable of effectively using tools with more than two or three flutes

Buy Cutting Tools

Purchasing Checklist

Spark recommends the following guidance for purchasing cutting tools. There may be projects which require modification of these recommendations, but members are advised to talk with the Woodshop Leads before buying specialty cutting tools.

| Description | Value |

|---|---|

| Shaft or Shank Diameter | 1/4-inch (0.25 inches)

or 1/8-inch (0.125 inches) |

| Cutting Diameter | Minimum: 1/32-inch (0.0312 inches)

Maximum: 1/4-inch (0.25 inches) |

| Cutting Length | Greater than max depth for intended use |

| Center-cutting | Yes |

| Tip Style | Square, fishtail, or V-groove recommended |

| Flute Style | Straight or Up-cut |

| Flute Count | Fewer than 3 |

Sources

While a variety of inexpensive cutters sourced from China are available on Amazon, a better cutter leads to cleaner cuts for a longer time. Spark recommends the following brands for reliable quality. They may be purchased from a variety of suppliers.

- Inventables

- As the Easel software is written by Inventables, bits purchased from them are usually already defined in the software

- Amana Tools

- LMT Onsrud

- Vortex Tools, Inc