Difference between revisions of "X-Carve: Example Machine Setup"

| Line 63: | Line 63: | ||

|- | |- | ||

! scope="row" | Step 1: | ! scope="row" | Step 1: | ||

| − | |[[file:WS X-Carve ClampParts.jpg| | + | |[[file:WS X-Carve ClampParts.jpg|400px|center]] |

| | | | ||

As shown to the left, the workpiece is red with a white core. Two pieces of brown tempered hardboard* are being used as spoil boards. | As shown to the left, the workpiece is red with a white core. Two pieces of brown tempered hardboard* are being used as spoil boards. | ||

| Line 78: | Line 78: | ||

|- | |- | ||

! scope="row" | Step 2: | ! scope="row" | Step 2: | ||

| − | | [[file:WS X-Carve ClampAngleGood.png| | + | | [[file:WS X-Carve ClampAngleGood.png|400px|center]] |

| | | | ||

Clamps should be assembled by: | Clamps should be assembled by: | ||

| Line 91: | Line 91: | ||

|- | |- | ||

! scope="row" | Step 2A: | ! scope="row" | Step 2A: | ||

| − | |[[file:WS X-Carve ClampAngleBad.png| | + | |[[file:WS X-Carve ClampAngleBad.png|400px|center]] |

| | | | ||

* Avoid clamping setup which slope down from the workpiece | * Avoid clamping setup which slope down from the workpiece | ||

| Line 97: | Line 97: | ||

|- | |- | ||

! scope="row" | Step 3: | ! scope="row" | Step 3: | ||

| − | |[[file:WS X-Carve ClampArrangement.jpg| | + | |[[file:WS X-Carve ClampArrangement.jpg|400px|center]] |

| | | | ||

* At least two clamps are required to hold a workpiece in position. More are recommended whenever possible. | * At least two clamps are required to hold a workpiece in position. More are recommended whenever possible. | ||

| Line 106: | Line 106: | ||

|- | |- | ||

! scope="row" | Step 3A: | ! scope="row" | Step 3A: | ||

| − | |[[file:WS X-Carve ClampCrashed.jpg| | + | |[[file:WS X-Carve ClampCrashed.jpg|400px|center]] |

| | | | ||

Careless clamp placement can result in damage to the clamp arms, as shown to the left. The left clamp arm is in good shape; the other two have suffered from careless clamp placement. | Careless clamp placement can result in damage to the clamp arms, as shown to the left. The left clamp arm is in good shape; the other two have suffered from careless clamp placement. | ||

Revision as of 01:35, 29 May 2023

This tutorial is Part 2 of the X-Carve Router practice example. This portion of the example will explain parts of the X-Carve table at Spark, and how to mount the material to the machine table, install the cutting tool, and set the router speed. If you haven't yet, go complete Step 1 first.

| Login to Easel and Start a New Project |

| Part 1: Creating Geometry and Features |

| Part 2: Setting Up the Machine |

| Part 3: Carving the Part |

Approaching the X-Carve

The X-Carve machine is near the main entry door into the Spark Woodshop. As you approach the machine, you'll see the following parts:

| |

|

The important part of the controller is the emergence stop, usually shorthanded to E-stop. It is the large red button on the controller, and is actuated by pressing straight down on it. This will immediately stop the motion of the machine, but will not stop the router spindle. The router spindle is controlled manually, and must be shut off separately. Don't be afraid to use the E-stop if the machine is doing anything unexpected. To reset the E-stop after correcting the problem, twist the red portion of the button clockwise. It will spring up and the X-Carve will be ready to run again. | |

|

Pulling out the cart under the machine gives access to the tool tray. The tools should be returned to the tray whenever they are not in use. The image at left shows the various types of tools, divided by color:

|

Mount Material to Table

Prior to using the X-Carve the workpiece must be firmly mounted to the the machine table. This requires use of the clamping parts found in the top tray of the cart.

It is also important to ensure that a spoil board is used whenever cuts are made through the workpiece. A spoil board is a sacrificial panel which protects the bed to the machine from being cut into. Several instances of careless cutting are visible on the Spark X-Carve bed. Please help prevent any more damage!.

PRIOR TO WORKING ON THE X-CARVE TABLE, ENSURE THE E-STOP BUTTON IS PRESSED DOWN

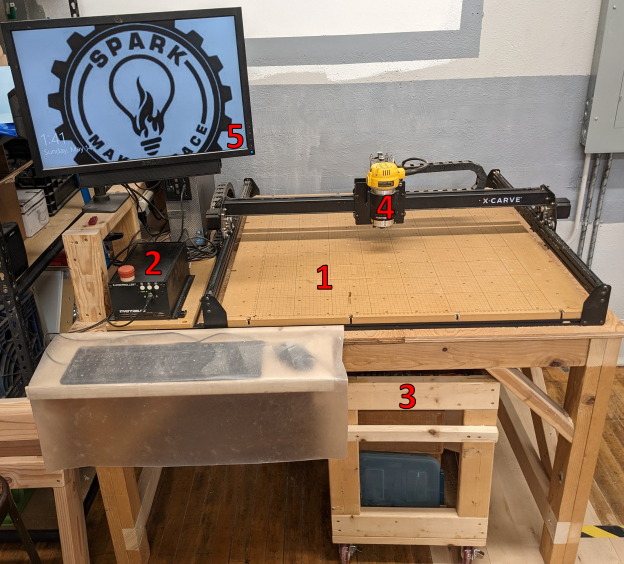

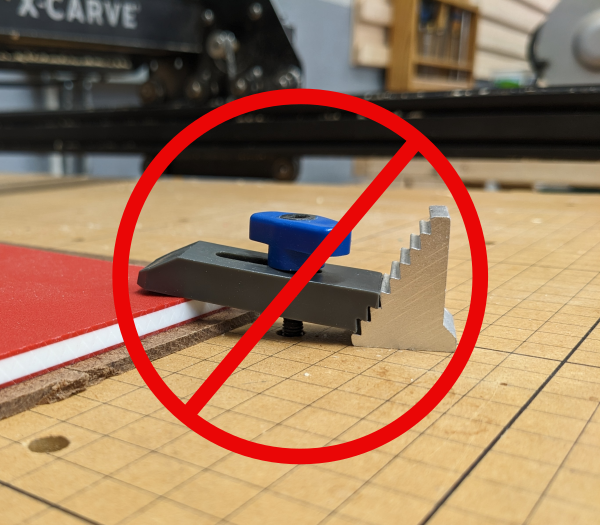

| Step 1: |

As shown to the left, the workpiece is red with a white core. Two pieces of brown tempered hardboard* are being used as spoil boards. At least two, ideally three or four, clamps should be used. One clamp is composed of three parts:

*also commonly called by the trade name Masonite | |

|---|---|---|

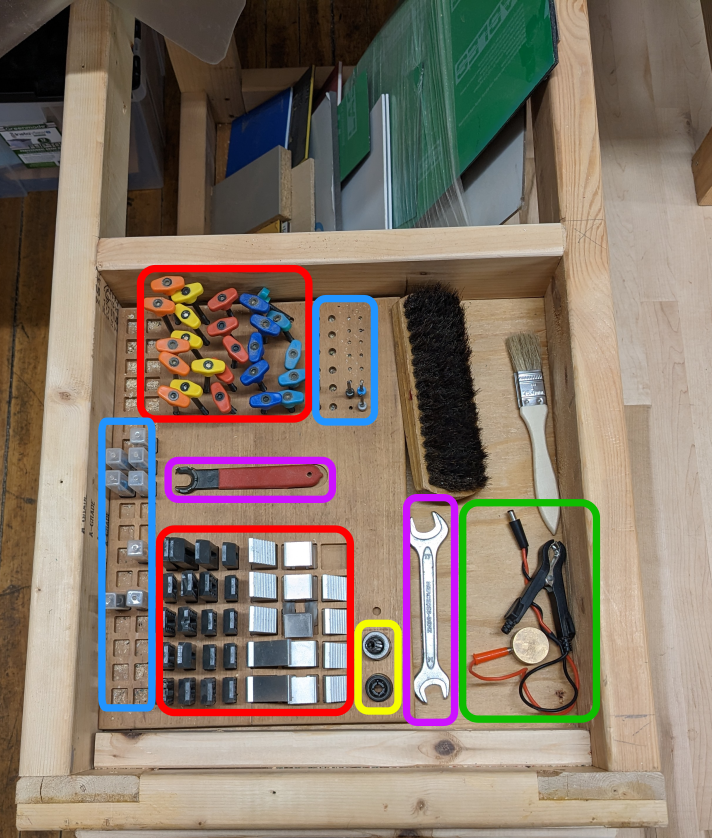

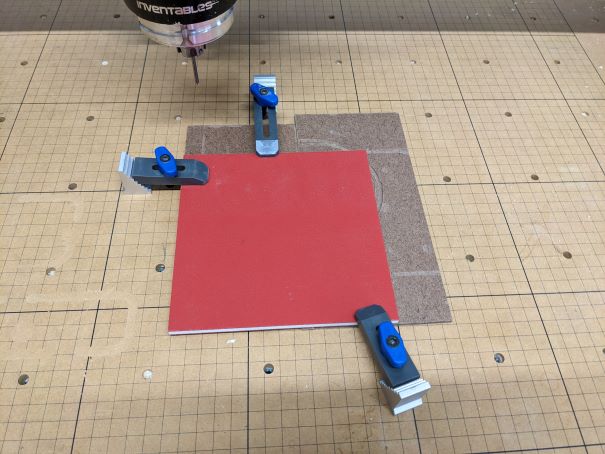

| Step 2: |

Clamps should be assembled by:

| |

| Step 2A: |

| |

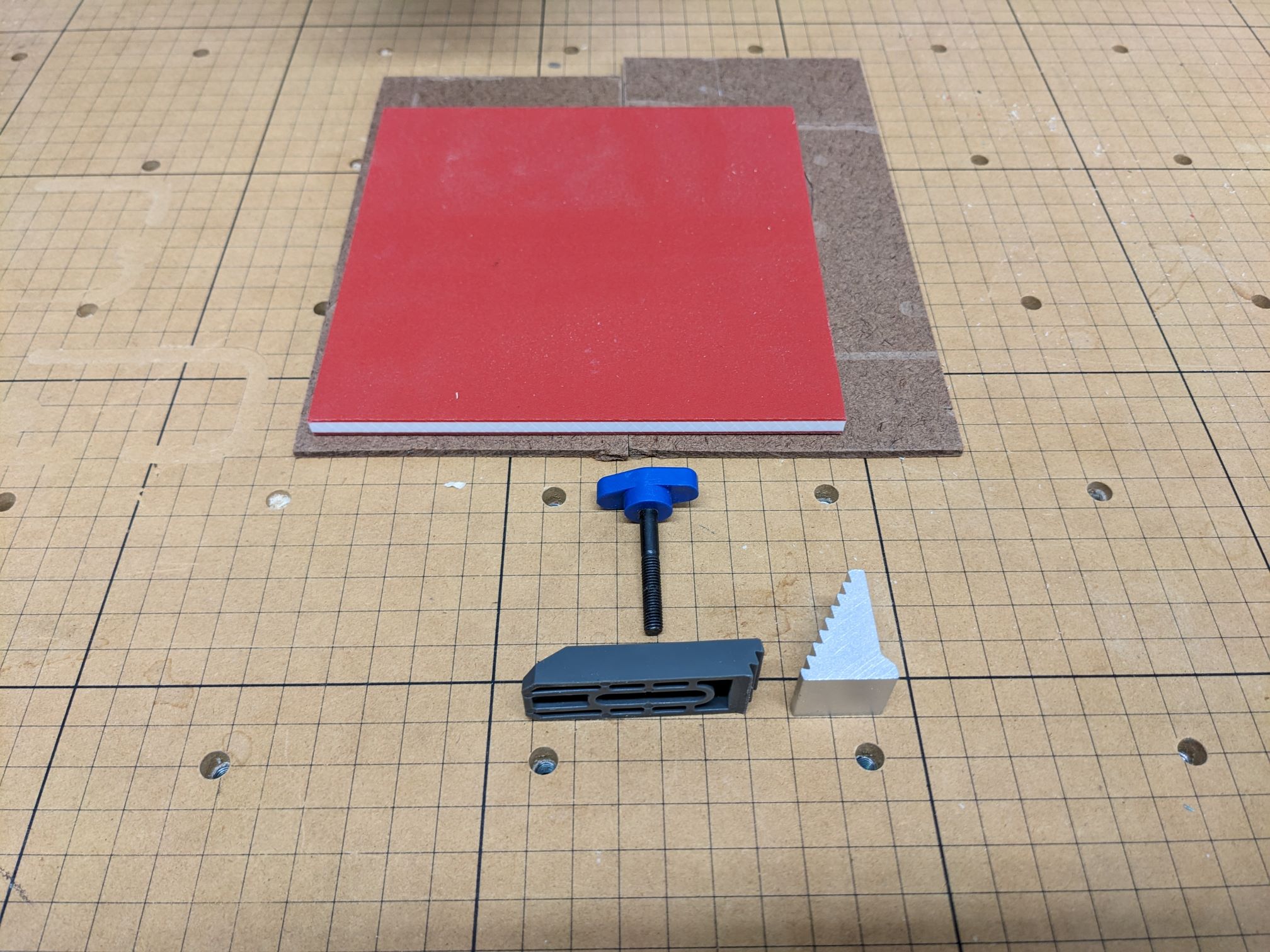

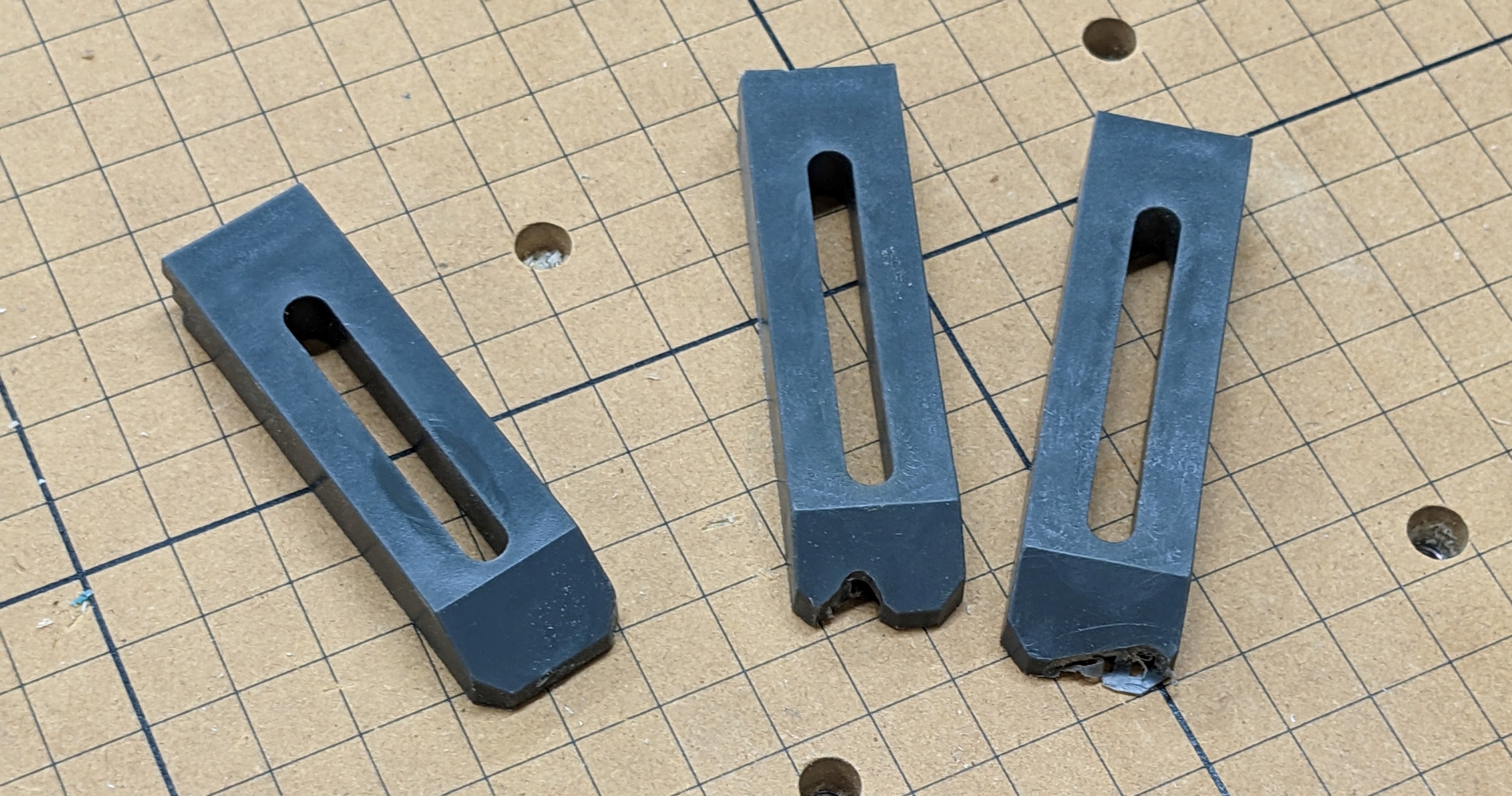

| Step 3: |

Note that in this case, three clamps have been used. Both the part and the spoil board have been aligned with the grid on the machine table. | |

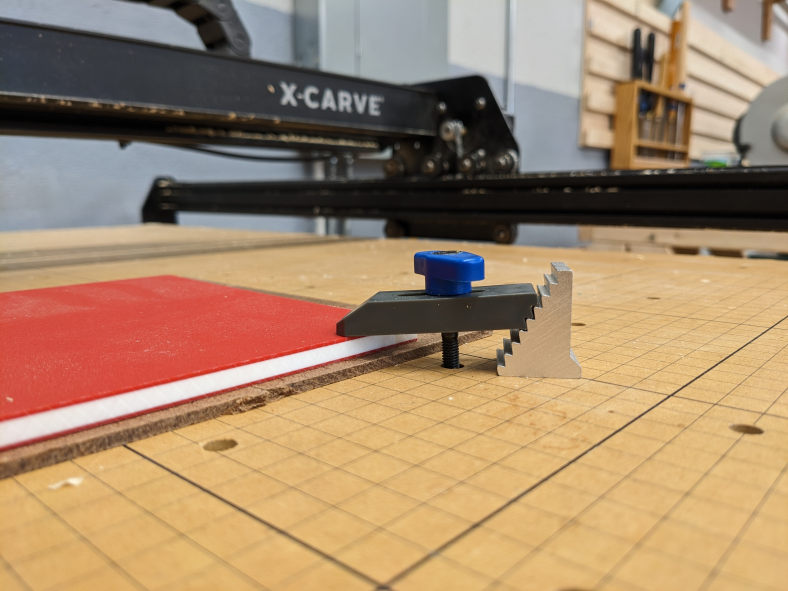

| Step 3A: |

Careless clamp placement can result in damage to the clamp arms, as shown to the left. The left clamp arm is in good shape; the other two have suffered from careless clamp placement. |

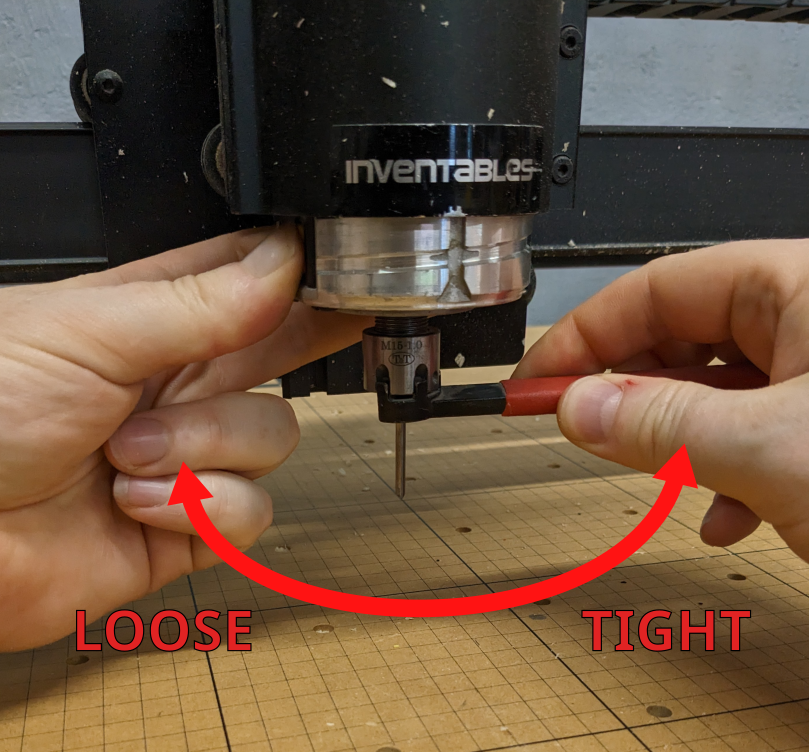

Install the Cutting Bit

The other major part of the machine setup is installing the cutting bit. The bit should match the bit definition in Easel.

PRIOR TO WORKING ON THE X-CARVE TABLE, ENSURE THE E-STOP BUTTON IS PRESSED DOWN

Final Checklist

Done with the install? Check the items below before moving on.

- The clamp arms are angled correctly

- The clamp screws are tightened

- The part is firmly held to the table - no wiggles, wobbles, or floppy corners

- The cutting bit is firmly held in the spindle collet

- Any spare clamp parts or assembly tools are back in the cart tool tray

Now you're ready to go to Part 3: Carving.